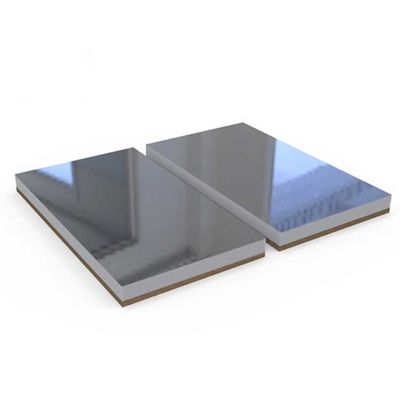

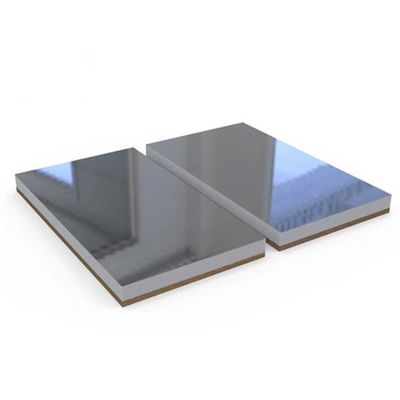

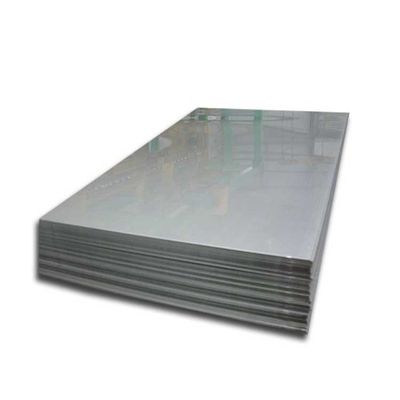

ASTM SS Iron 304L 304 321 316L 310S 430 Stainless Steel Sheet

What is the difference between 304 and 304L stainless steel?

The main difference between 304 and 304L stainless steel lies in their carbon content. Both alloys are part of the austenitic stainless steel family and have similar chemical compositions, including high levels of chromium and nickel, which provide excellent corrosion resistance.

The "L" in 304L stands for "low carbon," indicating that it has a lower carbon content compared to standard 304 stainless steel. Specifically, the carbon content in 304 stainless steel typically ranges from 0.08% to 0.10%, while in 304L stainless steel, it is limited to a maximum of 0.03%. This reduction in carbon content helps to minimize the formation of chromium carbides, which can lead to sensitization and intergranular corrosion in certain environments.

Due to its lower carbon content, 304L stainless steel is often considered more suitable for welding applications. The reduced carbon level minimizes the risk of sensitization during welding, which can occur when the carbon combines with chromium, depleting the chromium available for corrosion resistance. Sensitization can lead to intergranular corrosion and compromise the material's integrity.

In terms of other properties, such as mechanical strength, corrosion resistance, and appearance, 304 and 304L stainless steel are generally similar. However, the lower carbon content of 304L may result in slightly lower tensile and yield strength compared to 304 stainless steel.

In summary, the primary distinction between 304 and 304L stainless steel lies in their carbon content, with 304L having a lower carbon content to prevent sensitization and intergranular corrosion during welding.

DESCRIPTION

| Standard |

AISI ASTM GB |

| Place of Origin |

China |

| Model Number |

200 Series:201 202 |

| 300 Series:301 302 303 304 304L 309 309S 310 316 316L 321 904L |

| 400 Series:410 420 430 440 |

| Duplex stainless:2205 2507 |

| Type |

Flat/corrugated/checkered |

| Processing Service |

Bending,Welding,Decoiling,Punching,Cutting, Moulding |

| Surface Finish |

2B/No.1/Mirror Finish/Satin Polished |

| Delivery Time |

3-10 days |

| Payment terms |

30%TT Advance+70% Balance against the copy of bill of loading |

| Sample |

Sample Avaliable |

| Inspection |

Accept Thrid Party Inspection |

| Thickness |

0.3mm-100mm |

| Port |

Tianjin Shanghai Qingdao |

| Certification |

ISO9001 |

| Packing |

Standardsea worthy export packing or according to the customers' request. |

| Applications: |

Kitchenware,home appliances,construction decoration,stairs,refrigerated container,burner parts,exhaust parts of auto |

| Container Size: |

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)24-26CBM |

| 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)54CBM |

| 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High)68CBM |

Surface Treatment

| Item |

Surface Finishing |

Surface finishing methods |

Main Applications |

| NO.1 |

HR |

Heat treatment after hot rolling, pickling, or with treatment |

For without the purpose of the surface gloss |

| NO.2D |

Without the SPM |

Method of heat treatment after cold rolling, pickling surface roller with wool or eventually a light rolling a matte surface processing |

General materials,building materials. |

| BA |

Bright annealed |

Bright heat treatment after cold rolling , in order to be more shiny, cold light effect |

Automotive parts, home appliances, vehicles, medical equipment, food equipment |

| NO.3 |

Shiny, coarse grain processing |

The NO.2D or NO.2B processing timber No. 100-120 polishing abrasive grinding belt |

Building materials, kitchen supplies |

| NO.4 |

After CPL |

The NO.2D or NO.2B processing timber No. 150-180 polishing abrasive grinding belt |

Building materials, kitchen supplies, vehicles, medical and food equipment |

| 240# |

Grinding of fine lines |

The NO.2D or NO.2B processing timber 240 polishing abrasive grinding belt |

Kitchen appliances |

| 320# |

More than 240 lines of grinding |

The NO.2D or NO.2B processing timber 320 polishing abrasive grinding belt |

Kitchen appliances |

| 400# |

Close to BA luster |

The MO.2B timber 400 polishing wheel polishing method |

Building materials, kitchen utensils |

| HL(hair lines) |

Polishing line having a long continuous processing |

In a suitable size ( usually mostly No. 150-240 grit ) abrasive tape for as long as the hair, having a continuous processing method of polishing line |

The most common building materials processing |

| NO.6 |

NO.4 processing less than the reflection , the extinction |

NO.4 processing material used for polishing Tampico brushing |

Building materials, decorative |

| NO.7 |

Highly accurate reflectance mirror processing |

No. 600 of the rotary buff with a polishing |

Building materials, decorative |

| NO.8 |

Highest reflectivity mirror finish |

Fine particles of abrasive material in order polishing , mirror polishing with a polishing |

Building materials, decorative, mirrors |

SURFACE TREATMENT

PACKAGE&LOADING

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are manufacturer that specialized in stainless steel sheets (products) with kinds of surface finished processes.

2.Q: How long is your delivery time?

A:It takes around 3-5 days for the regular models, and 8 to 14 working days for the special sizes and processing. It is based on the order quantity and requirement.

3.Q: Do you provide samples ? Is it free or extra ?

A:Yes, we would send you small samples for free; the size is 80x110mm.And the sample book is 250x350mm. Most of models have stock, and also can be customized and need around 4 to 6 days.

4.Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance. Payment>=5000USD, 30% T/T in advance ,balance before shippment.

5.Q: How do you protect the stainless steel sheet surface?

A: We have a high request for our quality, and each plate must have the second layer PVC laser film, one layer is 7C thick, double lays are 14c thick.

6.Q: What is the usage of your products?

A: It is widely used for elevator and kitchen decoration, Luxury door , wall panel and indoor decoration, advertising board, ceiling corridor, hotel hall, storage rack and kinds of entertainment places, etc.

7.Q: Do you have any assurance for your stainless steel sheets?

A: It will have the mill test for quality and material report for each shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!